TECHNOPOLYMERS

HIGH PERFORMANCE

TECHNOPOLYMERS WE CAN USE IN OUR PROCESSING

ABS - PA6 - PA66 - PBT - PC - PC ABS - PMMA POM - PP - PE - SAN - SBS - TPA

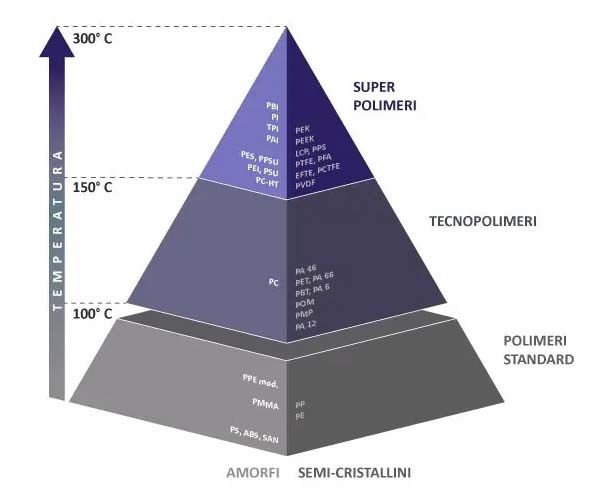

There are over 20 distinct types of thermoplastic materials that can be transformed with the injection molding process. These include base polymers (or standard polymers), technopolymers, high-performance polymers (or superpolymers) and elastomers. We are able to propose the combination of the basic properties of these thermoplastic materials and with the addition of additives, fillers and reinforcements, it is possible to carry out processing and carry out the application characteristics of the final product as per the initial project. The thermoplastic materials are selected based on the final applications of the product which can be structural, aesthetic, functional, or electrically and thermally insulating or conductive, anti-wear/shockproof, antistatic, lubricated, dyeable, shielding: according to the requests it is identified and proposed the technopolymer suitable for the mechanical or structural characteristics of the product.

WHAT THEY ARE

Sono polimeri dotati di elevate caratteristiche fisico meccaniche quali: rigidità, tenacità, duttilità, lavorabilità, resistenza a temperature elevate che arrivano a 300° C, a carichi statici e dinamici e all'invecchiamento.

Le elevate prestazioni meccaniche in combinazione all’alta resistenza termica, fanno sì che i TECNOPOLIMERI trovino applicazione in numerosi settori industriali che necessitano di materiali e componenti particolarmente performanti in sostituzione anche a parti metalliche con un consistente abbattimento dei costi.

BENEFITS

The advantages are many: they have a reduced weight compared to metals and in case of shipment, the costs are reduced. The assembly of multiple metal molded pieces or castings fixed together can be replaced by a single injection molded part. They are not subjected to the wear of rust or oxidation, have greater chemical resistance and are not affected by the basic compounds that can corrode the metal.

WHY CHOOSE THEM

More and more used in mechanical components such as: gears, pulleys, bushings, screws, etc. It allows to use less raw material, requiring reduced production cycles, thus guaranteeing considerable savings. The components in TECHNOPOLYMERS are more versatile than those in metal, guaranteeing the same performances and in some cases, improving them.